Circular Welding SPM

Product Details:

- Material Stainless Steel

- Capacity 5 NOS Pcs/min

- Computerized No

- Automatic Grade Semi-Automatic

- Control System PLC Control

- Processing Type PLC Based

- Voltage 415 V Volt (v)

- Click to View more

Circular Welding SPM Price And Quantity

- 1 Unit

- 550000 INR/Unit

Circular Welding SPM Product Specifications

- Yes

- As per Requriments

- 1 Tons Kilograms (kg)

- PLC Based

- Stainless Steel

- 3 PHASE Volt (v)

- Semi-Automatic

- PLC Control

- 1.5 M X 1.2 M X 2 m Meter (m)

- 5 NOS Pcs/min

- No

- 415 V Volt (v)

Circular Welding SPM Trade Information

- Cash in Advance (CID)

- 50 Unit Per Month

- 10 Days

- Contact us for information regarding our sample policy

- All India

Product Description

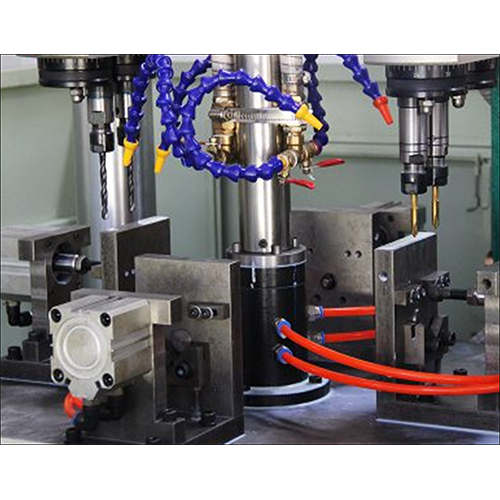

Circular Welding SPM

A super-fast, reusable welding process that creates high-performance joints between fast-curing epoxy composites involving a co-bonded thermoplastic interlayer that enables the design for circularity

One or two welding positioners carry out the circular welding. The welding positioner is a device that keeps the part tight and rotates it with a required rotational speed. This rotational movement can in 3 Axis.

In circular welding, the round part is positioned under the welding torch. The MIG or TIG welding machine starts the welding. A MIG welder is a welding machine that uses a metal feed wire to weld the parts. In a MIG welding machine (Metal Inert Gas) the application can be made on different metals such as aluminum, stainless steel, and steel, and on every thickness from 26-gauge sheet metal to heavy-duty structural plates.

The MIG welding feed wire also acts not only as an electrode but also as a filler. So the thickness of the sheet metal doesnït play a role here as the feed wire of the MIG welding torch can fill the space easily. Conversely, TIG welding (Tungsten Inert Gas) has a better finishing effect and higher quality.